Freshman ‘forges’ unique hobby

Normalize, rivet, face, oxidize, flux, wire brush, and forge welding.

These are words that often resonate in the mind of self-taught blacksmith Everest Gromoll. Gromoll, a freshman, often forges with his personal blacksmith forge, self-made from a pot and pan, during his free hours after school. Items created range from towel racks to knives to leaf ornaments to anvils.

“I’m currently a member of the Blacksmith Guild of the Potomac,” Gromoll said, who has been forging for a little over a year.

It was through the Lord of the Rings series that Gromoll was first introduced to forging and metal works at age four. Over time Gromoll refined the skills of refining metal by watching YouTube videos. Steel used for his hobby, Gromoll’s most standard metal, is acquired through scrap yards and unwanting owners.

“I found an old rusted out Studebaker in the woods,” Gromoll said. “It took eleven extension cords to get my angle grinder out there. After, we took apart the rest of the car using a sledgehammer.

Gromoll’s unique skill has received different reactions in the eyes of the community.

“Some people think it’s cool,” Gromoll said. “Some people think I’m crazy. Some people think I’m dangerous.”

Freshman Ian Champney, a longtime friend who recently asked the blacksmith to forge him a knife, expressed interest and appreciation in Gromoll’s hobby.

“I thought it [the knife] would be cool,” Champney said. It’s really well done. It looks pretty much flawless. I whittle [with it].”

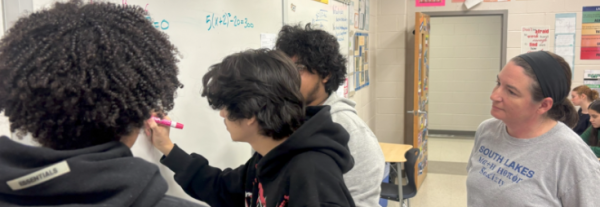

Gromoll’s math teacher, Karla Chustz, learned of Gromoll’s skill when she unknowingly asked the origin of one of his works. Since then she has experienced a growing curiosity in Gromoll’s work, especially in its context in the modern age.

“Now in the days of technology and phones, and everything that is instant [I] look at what he’s doing,” Chustz said. [Forging] takes time, care, and a measure of precision that I don’t see in kids now days. It’s amazing that he really enjoys that.”

Gromoll, who forges for about an hour or two each day with tools hand-made or acquired through swap meets, is currently attempting to master harder techniques such as forge welding which involves heating metal to the point of melting and then causing the pieces to adhere to each other with a hammer.

“It’s really tricky because you have to have a clean fire and you have to use flux to keep the scale from forming,” Gromoll said. “You [also] have to keep the oxygen out. It’s hard.”